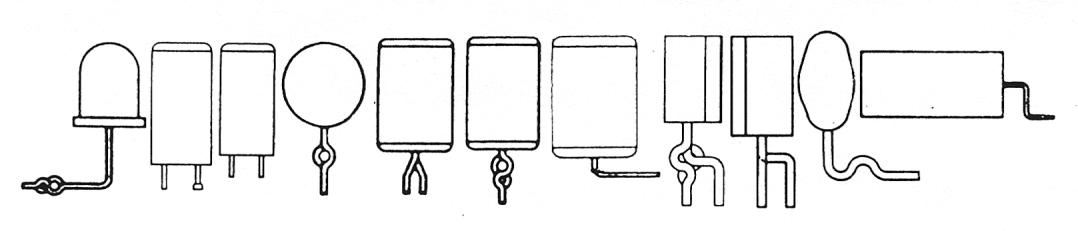

AUTOMATED CUTTING AND FORMING MACHINE FOR 2 AND 3 LEADED RADIAL COMPONENTS

The C092 was designed to produce complex radial forms for 2 and 3 leaded components.

The system can be configured for cutting, forming, multiple 90 bends, as well as 90

bending with or without a form (For bending and forming specifications please contact us).

Because the C092 only accepts components on tape, either reeled or ammo pack formats

are acceptable. Also because of its flexibility, the C092 allows the processing of components

taped on 12.7 or 15mm spacing by using easy to change tape guides and tools.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Cutting, stamping and bending device for radial components

The streckfuss model C 092 has been developed to process taped components with holepitches of 12.7 mm and 15 mm with one machine. To eliminate any kind of inconsistencies due to any kind of variances in taping, this machine is fitted with probing-unit that will verify the cut length.

The machine was developed with two processing units for multiple die sets. The inserts can be exchanged very quickly.Because of the dual processing-units a wide range of bending and stamping forms can be processed.

Components

Specifications

| Production Rate: | 4,200 – 6,300 pcs/hr |

| Machine Dimensions: | 650mm x 450 mm x 500 mm [26″ W x 18″ L x 20″ H] |

| Electrical Requirement: | 220v, 50/60hz, 0.12kw [110v, 50/60hz, 0.2kw] |

| Weight: | Weight. Approx 35 kg |

| Compress air: | 6 Bar |

| Pitch: | Min:2.5 mm, max: Form dependend |

| Holepitch: | 12.7 mm and 15 mm |

| Lead: | 0.4 to 0.8 mm |

| Component delivery: | reel or ammopack |

| Component outgoing: | loose |

| Operation: | engine (continuously variable) |

| Leistung: | 6.300 BE/h — without probing 4.200 BE/h — with probing |

| Options: | Electronic counter which cuts off the automat automatically when the pre-defined number of items is reached. roll-off block for all in trade reels |